TRANSFORM CHALLENGES INTO TRIUMPHS WITH THRELIX®.

- About TAQA

- What we do

- Overview

- Well Solutions

- Overview

- Coiled Tubing, Intervention & Stimulation

- Completions

- Drilling Solutions

- Cementing

- Well Testing

- Early Production Facilities (EPF)

- Wireline

- Frac

- Slickline

- Inspection

- H2S & Safety

- Plug & Abandonment

- TAQA Ventures

- Products & Technologies

- Resources

- Sustainability

Threlix®

Overview

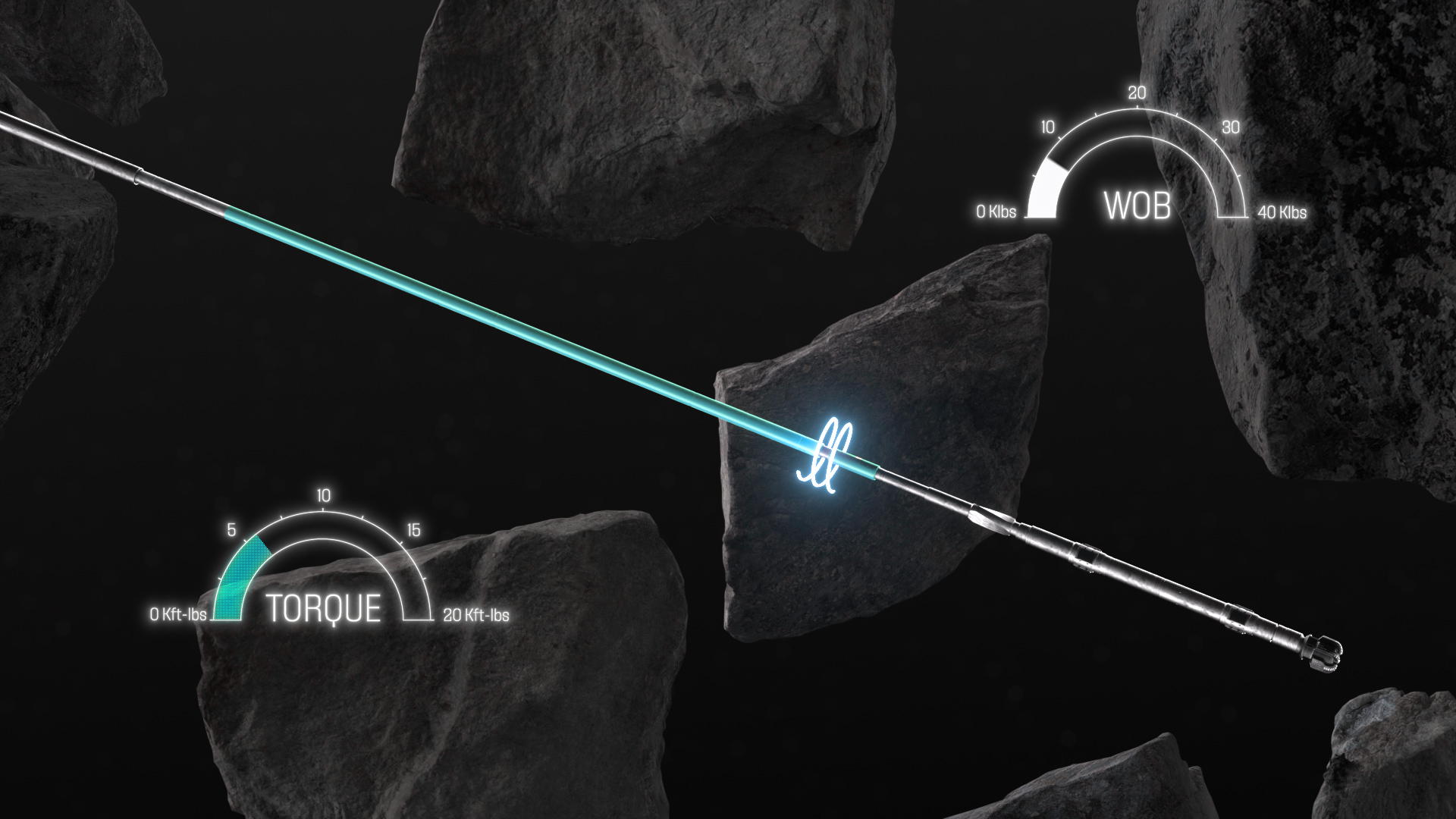

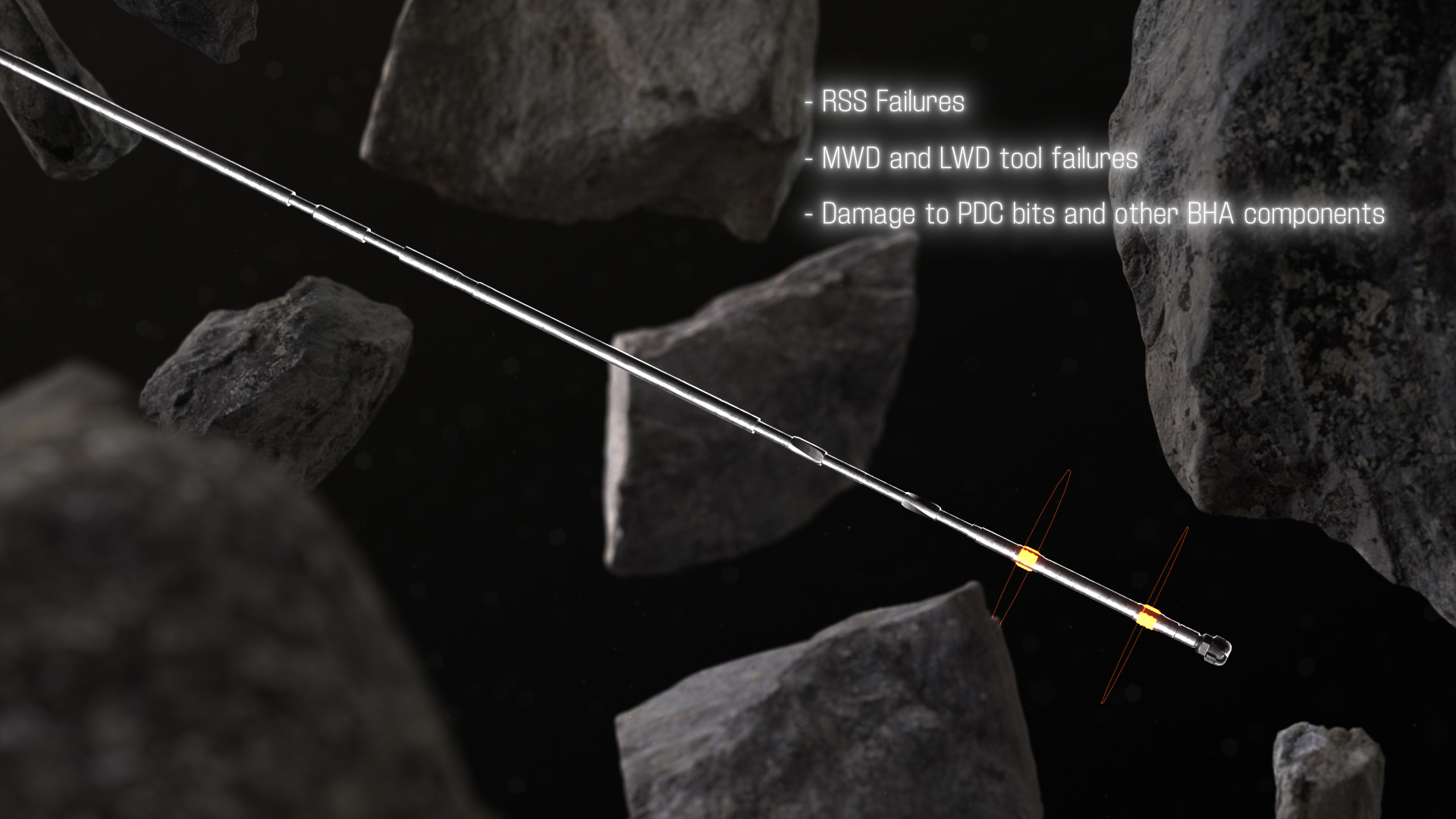

TAQA presents Threlix, a patented technology designed to assist operators in mitigating drilling dysfunctions while drilling with rotary steerable systems (RSS). By balancing downhole torque against downhole weight on bit (WOB), Threlix™ ensures a smooth and consistent depth of cut at the drill bit, effectively eliminating erratic torque, stick-slip, and HFTO (high-frequency torsional oscillation) which can lead to bit and downhole tool DBR’s, Tool failures and costly trips out of the hole.

Challenge

When encountering excess torque during drilling operations, Threlix instantly adjusts its length to maintain a consistent depth of cut at the bit interface preventing stick-slip scenarios, ensuring optimal drilling progress leading to exceptional performance, reduced damages, and minimized section times.

Application & Results

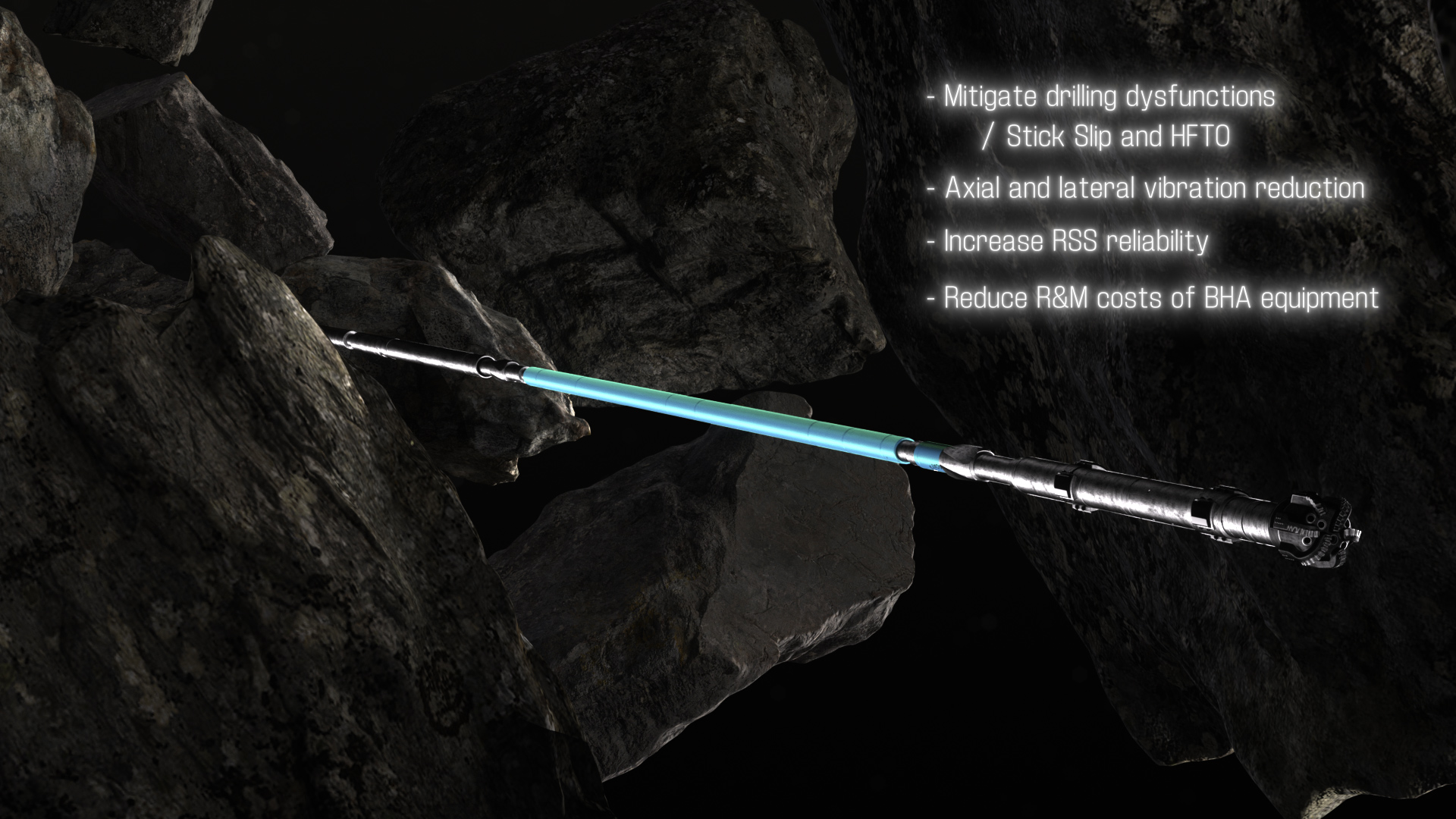

Threlix is engineered with a proprietary helical spring that facilitates both compression and extension, enabling it to meet any drilling application. Furthermore, its 100% sealed spring and spline sections significantly enhance downhole reliability and performance, eliminating the need for costly post-run maintenance and reducing associated risks.

Main features

- BENEFITS

- Mitigate torsional vibrations – stick-slip and HFTO

- Increase RSS reliability

- Minimize damages to PDC bits, MWD, and LWD tools

- Decrease axial and lateral vibrations

- Reduce R&M costs of downhole drilling tools

- Reduce drilling time and costs

- FEATURES

- Proprietary helical spring design

- Components are fully enclosed and oil-sealed

- Compatible with all RSS

- Dual acting – extension, and compression

- Applications engineering support

Specifications

-

- Operates in Compression and Tension for maximum operating window

- 100% Oil Sealed internal components, minimizing damages from drilling fluids and R&M costs

- Proprietary Helical Spring design to reduce fatigue and increase reliability

- Full bore ID for minimal pressure drop across the tool

- High-torque internal connections

- High-Temperature configuration available

Datasheet

Resources

Threlix Animation - Transform challenges into triumphsContact us for enquries

Let's talk - What we do