EDMONTON, Alberta – September 15, 2025 – TAQA (Industrialization & Energy Services Company), a leading global provider of well solutions in the energy sector, today announced the launch of Esaar™ mud motor, its next-generation drilling tool engineered for durability, operational flexibility, and serviceability. Developed in direct response to field feedback, the Essar™ mud motor is tailored to meet today’s complex drilling demands, delivering reliable performance across a wide range of applications.

At the heart of Esaar™ is a custom mud-lubricated bearing pack engineered to excel in high-torque and corrosive environments. This robust design extends tool life and boosts operational reliability. Maintenance is streamlined with optimized bearings and housing that allow for rapid servicing and on-site adjustments, minimizing downtime and maximizing efficiency.

“TAQA’s Esaar™ drilling motors represent more than 50 years of downhole tool expertise, culminating in a design that prioritizes serviceability and reliability,” said Patrick Connors, TAQA Directional Technology Manager. “These motors are built to meet the cost and performance challenges of modern drilling environments, offering operators unmatched flexibility.”

Field-tested across verticals, curves, laterals, geothermal wells, and rotary steerable system (RSS) applications, Esaar™ mud motors have demonstrated exceptional versatility and dependability. Available in sizes from 4.75” to 11.75”, each motor can be fully customized with options including stabilized or non-stabilized, and straight or adjustable configurations.

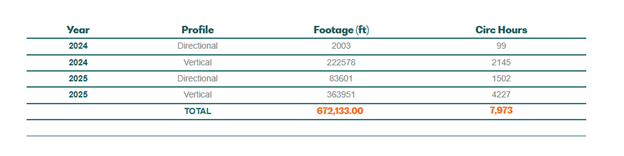

In recent field operations, Esaar™ mud motors delivered more than 672,000 feet of footage and logged nearly 8,000 circulation hours across both vertical and directional profiles, underscoring their durability and performance in demanding drilling environments. The chart below shares Esaar™ performance data from the past few years in the Middle East North Africa Turkey (MENAT) region.

At the heart of Esaar™ is a custom mud-lubricated bearing pack engineered to excel in high-torque and corrosive environments. This robust design extends tool life and boosts operational reliability. Maintenance is streamlined with optimized bearings and housing that allow for rapid servicing and on-site adjustments, minimizing downtime and maximizing efficiency.

“TAQA’s Esaar™ drilling motors represent more than 50 years of downhole tool expertise, culminating in a design that prioritizes serviceability and reliability,” said Patrick Connors, TAQA Directional Technology Manager. “These motors are built to meet the cost and performance challenges of modern drilling environments, offering operators unmatched flexibility.”

Field-tested across verticals, curves, laterals, geothermal wells, and rotary steerable system (RSS) applications, Esaar™ mud motors have demonstrated exceptional versatility and dependability. Available in sizes from 4.75” to 11.75”, each motor can be fully customized with options including stabilized or non-stabilized, and straight or adjustable configurations.

In recent field operations, Esaar™ mud motors delivered more than 672,000 feet of footage and logged nearly 8,000 circulation hours across both vertical and directional profiles, underscoring their durability and performance in demanding drilling environments. The chart below shares Esaar™ performance data from the past few years in the Middle East North Africa Turkey (MENAT) region.

With the launch of Esaar™, TAQA is redefining downhole motor performance, delivering durability, adaptability, and rapid service to help operators stay competitive in today’s high stakes drilling landscape. For more information on Esaar™, please visit: https://www.tq.com/solutions/drilling-solutions/directional-drilling/mud-motors/